A Biased View of Water Filtration Service

Table of Contents3 Easy Facts About Water Filtration Service ShownWater Filtration Service - An OverviewExamine This Report on Water Filtration ServiceGet This Report on Water Filtration Service

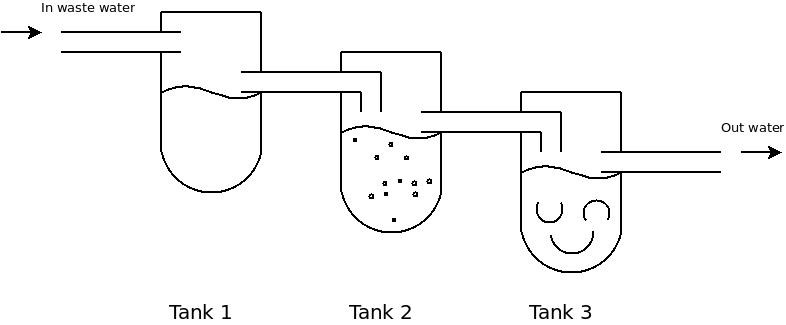

This starts in the aeration container - water filtration service. The primary function of the oygenation container is to pump oxygen into the tank to encourage the break down of any kind of natural product (as well as the growth of the germs), in addition to make certain there suffices time for the natural product to be broken down.

This process is taken care of to supply the best problems for bacterial development. Oxygen gas [O2] degrees below 2 ppm will exterminate the bacteria, minimizing efficiency of the plant. Dissolved oxygen monitoring at this stage of the plant is critical. Ammonia and nitrate dimensions are usual to measure exactly how reliable the microorganisms are in transforming NH3 to N2.

Body is a surrogate indication for the quantity of organic material existing and is used to determine the performance of organic product malfunction. There are a number of other tests used to ensure optimum natural product breakdown (and also body decrease) such as measuring p, H, temperature level, Dissolved Oxygen (DO), Overall Suspended Solids (TSS), Hydraulic Retention Time (flow rate), Solids Retention Time (quantity of time the bacteria is in the oygenation chamber) and also Mixed Liquor Suspended Solids.

Our Water Filtration Service Diaries

Stage 5 Additional Clarifier Treated wastewater is pumped into a secondary clarifier to allow any kind of continuing to be natural sediment to settle out of treated water circulation. As the influent exits the aeration process, it flows into a second clarifier where, like the primary clarifier, any type of extremely small solids (or fines) sink to the bottom of the tank.

Part of this triggered sludge is returned to the aeration container to increase the bacterial concentration, assistance in proliferation, and also speed up the breakdown of organic product. The unwanted is thrown out. The water that flows from the second clarifier has actually considerably lowered natural material and needs to be coming close to expected effluent specs.

With the improved focus of bacteria as part of the oygenation phase, there is a need to test the outbound effluent for bacteria presence or absence as well as to disinfect the water. This makes sure that more than specified concentrations of germs are not released right into the environment. Chlorination is one of the most usual and affordable kind of disinfection but ozone and UV sanitation are likewise boosting in popularity.

Americans are privileged to reside in a nation with among the best water materials on the planet. According to the Environmental Protection Firm (EPA), 286 million people obtain their alcohol consumption water from an area water supply. To make water safe for public usage, it undergoes a series of therapies and tests on its journey from source to tap.

Not known Facts About Water Filtration Service

Health Threats of Drinking Contaminated Water Drinking water has the potential to be infected at its resource along with within the water circulation system. The EPA is in charge of managing the high quality of the alcohol consumption water additional resources in the U.S. as well as sets the optimum allowable degrees for concentrations of different contaminants (water filtration service).

This basic, inexpensive application is a needed pre-treatment action prior to the filtering as well as disinfection phases. 3. Filtering At this phase, the floc bits next page have resolved to the base of the water system as well as the clear water awaits additional therapy. Purification is essential as a result of the little, liquified bits that are still existing in clear water, that include dust, parasites, chemicals, viruses, and also microorganisms.

Rapid sand purification is a cost-intensive method compared to other alternatives, requiring power-operated pumps, routine cleansing, circulation control, knowledgeable labor, as well as constant energy. 4. Disinfection The last in the community water therapy procedure involves including an anti-bacterial such as chlorine or chloramine to the water system. Chlorine has been utilized considering that the late 1800s.

The Ultimate Guide To Water Filtration Service

This is various than the type that can hurt the interior air quality around pool. The primary effect of the disinfection procedure is to oxidize and eliminate natural matter, which protects against the spread of parasites, viruses, and bacteria that might remain in the drinking water. Decontaminating likewise serves to protect the water from bacteria it may be subjected to throughout distribution as it is this contact form piped to houses, schools, organizations, as well as other destinations.

Throughout waterfall de-gasification procedure, the water drops over a collection of steps. Oxygen bubbles can attach to particles in the water that have formed a fluffy precipitate called floc, creating these particles to drift instead than sink.

If taste as well as smell in the water ends up being elevated throughout cold weather, and the granular triggered carbon (GAC) system, (Phase 6), is not in usage, PAC is included in the Flocculation phase to assist in minimizing taste and smell. In this phase, aluminium sulphate (alum) is intensely combined with the water.